- 网站导航 -

Address:Home > Products > Binzel series welding gun >

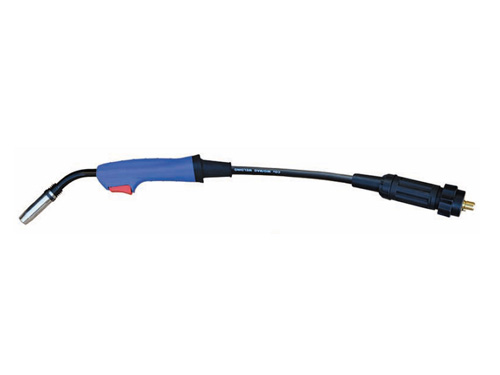

The BRK250A Air Cooled MIG Welding Torch is designed for medium-duty welding applications, typically used with MIG (Metal Inert Gas) welding systems. Here are some key features, advantages, and maintenance tips related to this torch:

Key Features:

Air-Cooled System:

The BRK250A uses an air-cooled mechanism to prevent overheating during welding. This system works by dissipating heat through airflow around the torch, making it more suitable for lighter to medium-duty welding tasks.

Amperage Rating:

Rated at 250 Amps, this torch is ideal for handling medium current welding tasks, allowing it to be used for various types of metal fabrication jobs.

Durability:

Constructed with high-quality materials, the BRK250A is designed to withstand rugged use in industrial settings while offering long-lasting performance.

Lightweight Design:

The torch is relatively lightweight, which reduces fatigue during long welding sessions, improving operator comfort and efficiency.

Ergonomic Handle:

Designed with an ergonomic grip, the BRK250A torch is comfortable to use and allows for greater control during welding, helping to produce cleaner, more precise welds.

Compatibility:

This torch is compatible with a range of wire feed units and can handle different types of wire such as steel, stainless steel, and aluminum.

Replaceable Consumables:

The BRK250A comes with replaceable nozzles, contact tips, and gas diffusers, making it easy to maintain and ensuring consistent welding quality.

Advantages:

Efficient Cooling:

The air-cooled system helps in maintaining the torch's temperature within an acceptable range, ensuring the equipment doesn't overheat during welding jobs.

Versatility:

Suitable for various applications, such as automotive repairs, metal fabrication, and general light to medium industrial tasks.

Easy Maintenance:

With simple consumable replacement and minimal need for complex maintenance, the torch is easy to keep in top working condition.

Cost-Effective:

Air-cooled torches like the BRK250A tend to be more affordable compared to water-cooled models, offering a good balance between performance and price for medium-duty tasks.

Maintenance Tips:

Regularly Clean the Torch:

Remove spatter and debris from the torch nozzle and contact tip after every welding session. This will prevent clogging and ensure stable gas flow.

Inspect the Cable:

Check for any wear or damage on the torch's power cable. A damaged cable can reduce efficiency and pose a safety hazard.

Replace Worn Consumables:

Regularly inspect and replace the contact tip, nozzle, and gas diffuser when worn. Worn parts can lead to poor weld quality and increased spatter.

Ensure Proper Gas Flow:

Ensure the shielding gas (like Argon or CO2) flows correctly. Blockages in the gas system can lead to welding defects such as porosity or oxidation.

Avoid Overheating:

Even though the BRK250A is designed to handle medium-duty tasks, avoid pushing the torch beyond its rated capacity to prevent premature wear and potential overheating.

Store Properly:

When not in use, keep the torch stored in a clean and dry location to avoid damage from dirt, moisture, or impact.

The BRK250A Air Cooled MIG Welding Torch offers reliability and ease of use, making it a popular choice for MIG welders who require a balance of performance and comfort.